Content

Many residents of Russia love to feast on cucumbers in winter. It is nice to open a jar of products that the greenhouse for cucumbers gave with your own hands. Cucumbers are vegetables that can never be abundant. In our country, they are the most common vegetable for pickling. In summer, one cannot do without them when preparing salads. They are good with kebabs and just boiled potatoes. You can increase their yield on your own plot by building a greenhouse or greenhouse.

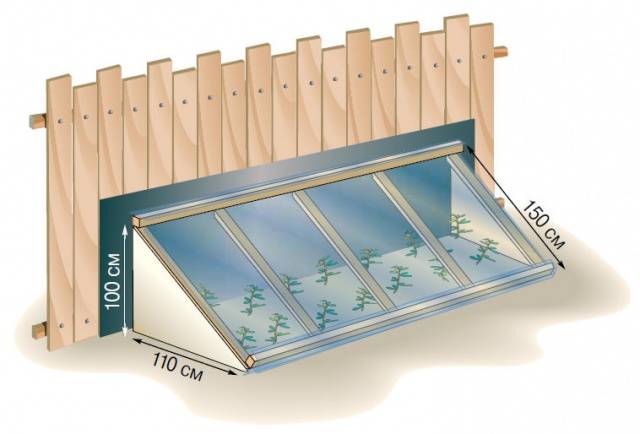

Greenhouse on a personal plot

Grow cucumbers in conditions of the harsh climate of our country and it is impossible to get a bountiful harvest without a greenhouse or greenhouse. When protected from the elements, vegetables grow faster. The crops are harvested from the beds much earlier and in greater quantities. A properly equipped do-it-yourself cucumber greenhouse provides plants with protection from pests and diseases. Most often, cucumbers are grown in greenhouses. This is a small temporary structure, which is assembled in spring. Above the greenhouse is closed with a film. If the film is removed, fresh air will flow to the plants.

The greenhouse is being built above the greenhouse and is a more capital structure. A man walks around the greenhouse to his full height, caring for plants.

Greenhouses are covered with foil, glass or cellular polycarbonate. Film is used very rarely nowadays. The most commonly used polycarbonate. A foundation is usually built under the greenhouse, which serves to protect the fertile soil from freezing in winter. In construction, such a structure costs several times more than a greenhouse. For this reason, some gardeners and gardeners prefer to build a cheap greenhouse.

For the construction of a greenhouse, a capital foundation is not required. Usually, tools and materials are used to build a greenhouse:

- hammer;

- wood screws or screws;

- furniture stapler;

- screwdriver;

- saw-hacksaw;

- roulette;

- fishing line or twine;

- wood;

- roofing material;

- sand and crushed stone;

- polyethylene film.

The base of the greenhouse is being built from wood, inside which there will be a bed with plants. Gravel mixed with sand is poured into the base of the ridge. From above, the ridge is covered with fertile soil. From above, the greenhouse is usually closed with a film. It can be different:

- reinforced;

- polyvinyl chloride;

- polyethylene hydrophilic;

- polyethylene light-converting.

Reinforced foil lasts approximately 3 years. Polyvinyl chloride film has good protective properties from ultraviolet rays. Its service life is measured in 3-7 years. Polyethylene hydrophilic film does not accumulate condensate on its surface, which tends to accumulate inside the greenhouse. The greenhouse can have a very low construction.

Its frame can be made of metal or plastic arcs.

The place for building a greenhouse should be bright, but not windy. There should be a little space around it for assembly and repair of the structure. The best orientation of the greenhouse is from west to east.

Its sizes can be very different. The height is usually about a meter. Inside the greenhouse, 1 or 2 ridges with a width of about 60 cm are equipped. The length can be any. A drawing of a greenhouse must be done in advance, so that later not to be mistaken in size. Often this structure is assembled entirely from wooden slats.

Greenhouse construction

Almost all summer residents and gardeners build capital greenhouses on the site. They are used to grow various crops, including do-it-yourself cucumbers.They build a greenhouse from a lot more materials. After all, its height is about 2.5 m. It has a foundation underneath.

For its construction, you can use tarred boards. They are installed on the edge, then fastened with corners. The service life of such a foundation does not exceed 5 years. It is even better to dig pieces of pipes into the ground, to which the arcs of the frame are subsequently attached.

Foam concrete blocks are often used as a foundation. They are laid out around the perimeter of the future greenhouse. From above, wooden beams are attached to them with anchor bolts. The greenhouse frame is later attached to these beams. The optimal sizes are considered to be:

- length of the structure - 4.5 m;

- its width is 2.5 m;

- height - 2.3 m.

For construction you need to prepare:

- arcs made of metal, plastic or wood;

- bricks (maybe not new);

- processed boards;

- shelter material;

- window frames;

- wooden blocks of different sizes;

- biofuels in the form of humus, peat or manure;

- apparatus for welding a metal frame;

- grinder for cutting blanks;

- hacksaw for wood;

- hacksaw for cutting metal;

- electric drill with drills;

- screwdriver;

- furniture stapler for stretching the film;

- sharp knife;

- scissors;

- hammer;

- construction level;

- plumb line;

- spanners;

- roulette.

As a material for covering the greenhouse, you can use a film, cellular polycarbonate or glass. Condensation can accumulate under the film and cause fungal infections. Polycarbonate does not suffer from this feature.

Preparatory work

Building a greenhouse is more difficult than building a greenhouse. First you need to choose a place to place it. It is advisable to locate the greenhouse in the direction from west to east. The place should be fairly level, close to the house. There should be no trees nearby. Next, you need to make the foundation.

For a permanent foundation, a strip structure is made of bricks or building blocks. A ditch is dug with a depth of 20 cm and the material is laid out. Above ground level, the foundation can rise up to 50 cm. Waterproofing is laid on it and the frame of the greenhouse is installed. The frame can also be attached to the beams previously laid on the foundation.

Ridges are formed inside the greenhouse.

Biofuel is placed under them and covered with a layer of fertile soil. When installing the cover, you should provide for and leave the vents for ventilation. They are usually made at the end of the greenhouse. Electric heaters and stoves are used for heating. For the active growth of cucumbers, a wire is pulled in the upper part of the greenhouse. A piece of twine is lowered from it to each bush of plantings. Then the cucumbers will curl along these strings.

Conclusion on the topic

Greenhouses and greenhouses have long become an attribute of any land suburban area. It is not very difficult to make them. The main thing is to choose the right place for their location.

A greenhouse is a more complex structure than a greenhouse.

Its frame is installed on the foundation. The frame is made of wooden blocks, metal and plastic pipes. The entire structure is assembled with nails, screws, screws, bolts and welding. It is good to use old frames with glass. The side surfaces and the roof were previously covered with foil. It has several disadvantages, so today glass or polycarbonate is most often used.

The optimum greenhouse height is 2.3-2.5 m. The width and length can be of various sizes. Most often, 2 beds are arranged in a greenhouse. A distance of 30-50 cm is left between them. All this allows the owners to walk around the structure in full growth. It is imperative to leave the vents for ventilation. Many people install automatic systems for watering plants, all kinds of heating devices in the greenhouse. They allow you to use the greenhouse all year round.