Content

Cage keeping chickens and quails per egg is usually done on large farms. However, now this technology is gradually becoming in demand in private farmsteads. The reasons may be very different: lack of space for keeping a large number of livestock, one shed for poultry and pigs, etc. This technology is not difficult for a private trader to master, but to translate it into reality you need to do chicken cages layers or quails.

The positive side of chicken cages

There are many opinions about the cage content of birds per egg. With quails, everything is clear. There is simply no other way to keep a wild bird at home. Why should the chicken suffer? Let's take a look at the benefits of cellular content:

- the cage completely allows you to exercise control over the laying hen;

- closed space allows you to provide optimal conditions for year-round egg production;

- the cage protects the hen from predators, and also facilitates the veterinary care of the livestock;

- a battery can be built from the cages, which will allow you to keep many layers in a small area;

- saving feed due to the fact that it is not eaten by wild birds.

It is with the cellular content of laying hens that 100% egg safety is ensured. In the yard, the bird finds its nest in any secluded place, where often a person is unable to reach. Eggs simply remain to disappear somewhere under a pile of firewood or they are eaten by other animals.

In the video, the cellular content of chickens:

Why a closed life is bad for layers

At home, building cages and populating chickens there is easy. How will an enclosed space be rated by hens? Let's look at the negative aspects of chicken cages:

- The limited space oppresses a moving bird. Being motionless, the hen does not waste its energy, which means that it eats less. Saving feed is a plus, but metabolic disorders occur, which affects a decrease in egg production.

- In an enclosed space, the laying hen cannot get vitamin D from the sun. This affects the quality of the eggs. With cellular content, the yolk loses its rich color, acquiring a dull white tint.

- In the wild, chickens peck fresh grass, scoop worms out of the ground, catch insects, but they are deprived of such an opportunity when locked up. Reimbursement of mineral components to hens occurs due to artificial additives, and this already affects the taste of eggs.

If you like to eat only homemade chicken eggs, the cellular content of layers will not work for you. When there is no other choice at all, you can solve the problem by improving bird care. Firstly, layers can be transplanted into cages for the winter, and provide them with maximum space. Secondly, greens should be constantly included in the diet of chickens, and vegetables should be given in winter. A good result is obtained when arranging a solid floor with litter in a cage, although caring for a bird is more complicated.

The video shows a cage battery for layers:

Varieties of cage designs for layers

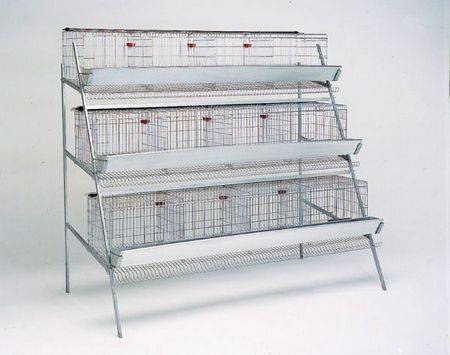

It is not difficult to build a drawing of a cage for laying hens with your own hands. One design resembles a rectangular mesh box.If desired, they can be connected in several tiers into a battery, as shown in the photo.

Before proceeding with the manufacture of the structure, you need to correctly calculate the size of the cage so that the hen is comfortable in it. It is considered normal if one cage is inhabited by seven layers. For such a number of birds, a mesh structure is made with a length of 60 cm, a width of 50 cm, and a height of 45 cm.With such sizes of cages for laying hens, the total floor area is 3000 cm2, and 428 cm falls on one bird2 free area.

Any cage design provides for its manufacture from a mesh with small cells. Only the front wall needs to be made of the coarse mesh so that the laying hen can reach the feed and water with its head. The only significant design difference is the floor. It is made solid and even for laying bedding or inclined from a net.

Chicken cage with bedding

When making any cage for laying hens, a frame is first made with your own hands. However, when arranging a solid floor, you will need to revise the dimensions. The width and depth of the cage is left unchanged, but the height is increased by 15 cm. This is due to the fact that part of the space is taken by the floor, assembled from 2 cm thick boards. Plus, the thickness of the litter is added to this.

The procedure for making a cage for laying hens is simple:

- A rectangular frame is assembled from a steel profile or wooden bar.

- The side walls and the ceiling are sewn up with a mesh with fine meshes. The front wall is fixed on mesh hinges with a mesh size of 50x100 mm.

- The floor is covered with an edged polished board.

The feeder and drinker are attached to the front wall so that all hens can easily reach them.

Laying cage with sloping floor and egg collector

The most convenient for laying hens are cages with an egg collector, in which the whole secret lies in the inclined arrangement of the floor. Once the hen has laid the egg, it does not roll on the floor, but gently rolls into the tray located outside the front wall. The convenience of this design also lies in the fact that the mesh floor does not require cleaning and laying of bedding. The droppings fall through the mesh cells directly into the pallet, from where it is periodically thrown out by the breeder.

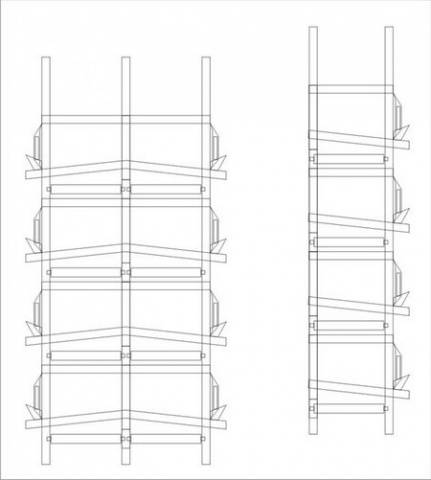

The photo shows a multi-tiered cage with an egg collector and an inclined bottom. It is this option that is convenient for home keeping laying hens. The structure of three or four tiers can be built on a solid frame. When making such a cage for laying hens with your own hands, you can use a wooden bar with a section of 50x50 mm, a steel profile or a corner. A galvanized profile for drywall is not bad, but for the rigidity of the structure, you will have to add additional lintels on the sides and on the floor.

The requirements for a multi-tiered structure are the same as for all laying cages:

- Hard floor. The net should be made of wire 3-5 mm thick, only this way it will not bend under the weight of chickens.

- It is advisable to make the side walls and ceiling not deaf. It is optimal to use a grid with a mesh size of 25x50 mm.

- The front wall is made of a mesh with cells of 50x50 or 50x100 mm. Instead of a mesh, you can fix the rods at a distance of 50 mm.

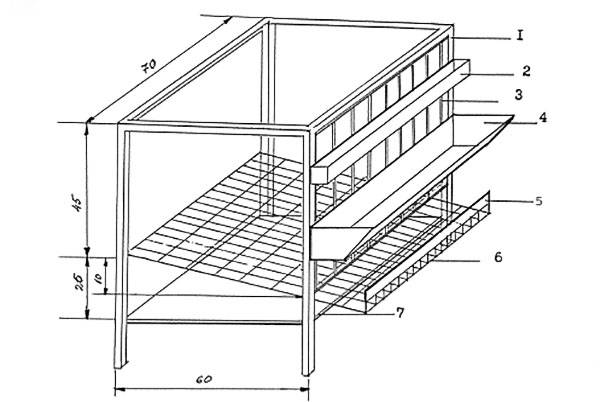

The photo shows a diagram of one cell. The rest on a common frame are made using the same technology.

So, the frame is ready for us, we proceed to the manufacture of the cage itself for layers:

- First, we horizontally attach any mesh to the frame. This will be the first floor. On the diagram, it is indicated at number 5. This net will hold the litter tray. The second inclined floor is made of fine mesh and is attached to the frame at an angle of 8-9about... On the diagram, it is indicated at number 4. About 15 cm of the sloped floor mesh is released beyond the front wall, and the edge is folded.Now you have a tray for collecting eggs.

- Between the first and second floors, a gap of at least 12 cm must be maintained. It is needed to insert the pallet. When the floor is ready, the walls and ceiling are installed from the mesh. The front wall of rods or coarse mesh is fixed with hinges so that it can be opened. In the diagram, the front wall is shown under No. 2.

- At this point, the structure is almost ready. Now the drinker is fixed to the front wall. On the diagram, it is designated # 1. Below the drinkers, a feeder is attached. It is displayed under # 3.

At this point, the cage with the egg collector is considered complete. It remains to make a pallet with sides from a sheet of metal, and install it between the first and second floors.

In the video, a cage with a litter removal system:

Features of the device of cages for quails

Now many poultry farmers have a desire to breed laying quail instead of chickens. These birds carry small eggs, but they are much healthier than chicken eggs. Houses quail cages made from any materials. Plywood, steel mesh, and even plastic vegetable crates are used. An egg collection tray is installed in front of the cage. Layers are provided with more space, but cages for quails left for fattening are limited in height. This allows the birds to gain weight faster and their meat becomes more tender.

The size of the quail housing is calculated based on the number of livestock and the purpose of the birds. The photo shows a table from which you can take such data.

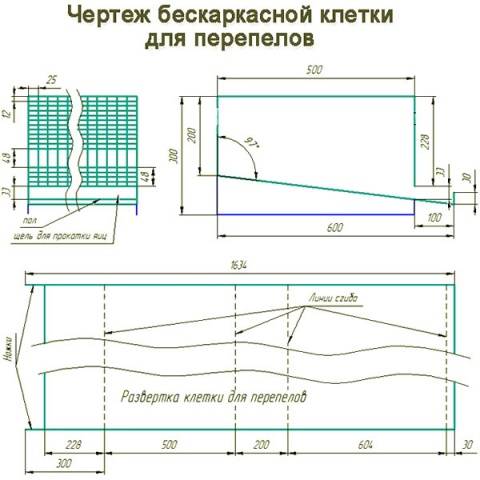

As for the manufacture of a quail cage, it practically does not differ from the design intended for laying hens, only the size is different. We will not consider options for housing made of plastic boxes and other scrap materials, but simply focus on a structure with an inclined bottom and an egg collector. The photo shows a drawing of such a cage, where it can be seen that it is arranged in the same way as for chickens. The same frame serves as the basis. The cage can be used as an independent structure with legs or fixed on a common frame by folding a multi-tiered battery.

If desired, a frameless cage can be made for quails. To do this, a pattern is simply built on the grid, after which a rectangular box is bent out of it.

The photo shows a drawing according to which you can cut out a frameless cage. But even in such a design, you need to remember the need for a pallet, and provide a gap for it under the inclined floor.

In the video, a quail cage:

As you can see, it is possible to organize housing for laying hens at home without any problems. The main thing is to have the desire and at least a small place where you can install the cells.