Content

Breeding broiler chicken is considered one of the most profitable poultry farming. The broiler grows quickly, produces excellent meat and large eggs. If the brood is regularly looked after and fed, properly maintained with vitamins and treated, up to a hundred well-fed chickens can be raised from March to October. But before buying a chicken broiler, you need to find a room for a mini-poultry farm or make a do-it-yourself chicken coop for broilers.

Conditions for growing broilers

Before choosing where and how to build a chicken coop for broilers, you will need to delve into and understand the technology of modern growing broiler poultry. The methods of feeding and keeping poultry, the chicken coops themselves for broiler chickens are somewhat different from the traditional village or summer cottage growing scheme:

- The vast majority of broilers for sale are raised in cages. Up to 10 adult broilers "live" in each cage;

- Chicken coops for keeping broiler chickens are lined up in the form of nets, placed on wooden or metal racks in several tiers. The nets are equipped with external feeders and drip troughs, which allows rational use of feed and water;

- The nature of the room chosen for the chicken coop practically does not affect the maintenance of the broiler, it is enough if the inside is from +12aboutFrom to +18aboutC for adult birds and compartment c + 35aboutC for chickens.

You can make a chicken coop for broilers in a utility room, a metal garage, as in the video:

or in a wooden shed, in principle it does not matter, the main thing is to withstand the necessary parameters of humidity, temperature and ensure good ventilation.

Otherwise, an outbreak of influenza or intestinal infection can destroy the entire brood of broilers in contact with each other in the chicken coop.

Therefore, when choosing a material and method for making a chicken coop, it is necessary to choose the right material and device so that disinfection and sanitation does not affect the design of cells and equipment in the chicken coop, as in the video:

Cage design

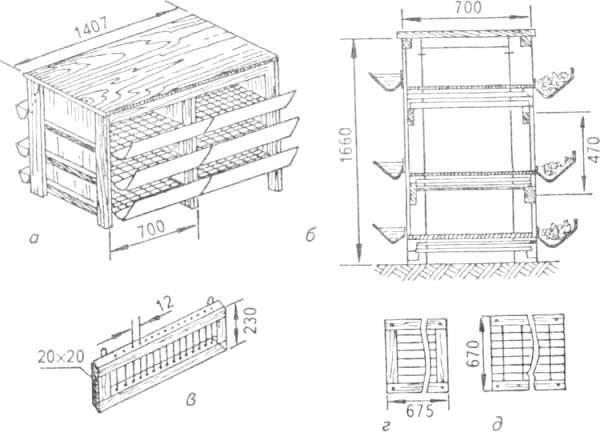

The sizes and shape of the cage for an adult bird are shown in the drawings and photos.

The height of the cage usually does not exceed 50 cm, which is quite enough for the normal maintenance of ten adult broilers in one net. But if the bird is often sick, it makes sense to increase the ceiling height to 55-60 cm, this will improve the access of fresh air, which the birds need so much. The most successful sizes and shape of a simple cell are shown in the photo.

The front mesh is made of two strips, the lower strip is covered with vertical rods with a pitch of 60 mm, the upper part is covered with fine steel mesh. The total height of the cage is just over 50 cm.

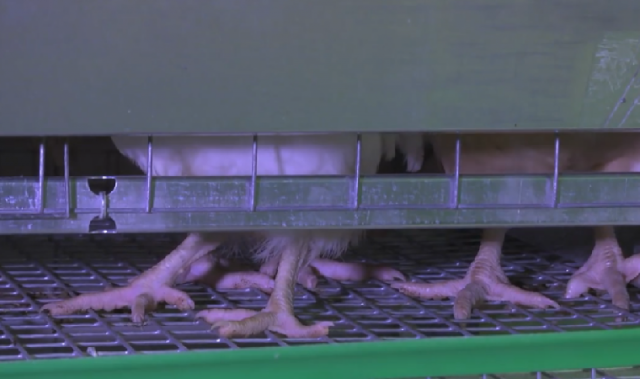

The floor is also made of fine mesh, which does not prevent the broiler from moving around the cage, but ensures that the droppings are dumped into the steel trays below.

The frame and side walls of the cage can be made of timber and boards, OSB board or plywood. Inside the cage, two drip-type drinkers must be installed in opposite corners of the cage.

How to properly build a chicken coop for keeping broilers

The easiest way to make a chicken coop for broilers is in a shed in a suburban area. Broiler house in the country somewhat different in type and size from the classic village chicken coop:

- Cages with birds are located in the hen house in at least three tiers, so the floor or floor covering must support the weight of the entire structure of the shelves, regardless of the structure of the walls and ceiling;

- The volume of the room and the height of the ceilings should be slightly larger than the usual chicken coop due to the need to provide good ventilation and a uniform flow of fresh air to the nets.

In addition, it is necessary to ensure normal insulation of the walls and ceiling, otherwise it will be quite difficult to heat a full-size chicken coop in cold weather. A broiler by nature has a rather weak immunity, easily gets sick, so the question heating the chicken coop especially important.

Arrangement of the foundation and walls of the chicken coop

The easiest way to build a chicken coop for broilers in the country is in the form of an extension to the house. Firstly, this way you can save on building materials and heating the room. Secondly, it simplifies the care and cleaning of the chicken coop in bad weather. Thirdly, a small predator, fox or weasel will not dare to meddle with broilers if there is a person nearby.

To build a chicken coop, a classic MZL foundation is used, attached to the base of a summer cottage or a summer kitchen, in the form of the letter P. Initially, you need to dig a trench 30 cm wide and 40 cm deep, install the formwork, lay waterproofing from roofing material and pour concrete.

A day later, the basement of the base of the chicken coop is laid out of bricks. A fine-mesh mesh is laid out on the blind area and the basement, at least 60 cm wide.It can be fixed to concrete and brick with dowels. Inside the foundation, a fertile layer of earth is removed to the depth of laying concrete, crushed stone 7-10 cm thick is poured, sheets of foam are laid, after which a concrete screed is poured.

The walls of the chicken coop can be made of bricks or assembled on a wooden frame made of edged boards.

Which option is best to build with your own hands in the country depends, first of all, on the availability of free funds and materials for construction. It is best to make a gable roof for broilers from boards and lumber residues. After the room has been treated with antiseptics and fire retardants, a roofing covering made of roofing material or bitumen shingles is glued.

Broiler house interior design

Cage racks can be made from timber or wooden slats. As a rule, racks are placed along the walls, leaving a passage in the center for cleaning the room and cages.

The floor is covered with a layer of sand with sawdust and the filling is changed at least once every two months. The average load per tier does not exceed 100 kg, so most of the parts of the cage and racks can be made of wood.

For professional broiler rearing, experts recommend using ready-made steel cages.

Experts recommend: before each bird planting for feeding, the rack and the entire chicken coop room must be thoroughly disinfected. In the process of growing a broiler, a bactericidal lamp is periodically brought into the chicken coop and turned on for 10-15 minutes. Of course, broiler cages are covered with wooden screens during sanitization.

For heating, you can use a ceiling infrared heater or a charcoal stove. If the chicken coop is built in the form of an extension to the house, then it is easier and more reliable to heat the room by diverting part of the flue gases from the stove in the house to the pipe registers installed along the cages with broilers.

Conclusion

Broiler cage rearing allows you to get good weight gain and productivity of layers. But the lack of mobility of a broiler always affects its health, therefore, the diet of poultry raised in a cage, as a rule, contains a large number of additives, growth stimulants and antibiotics. Such a decision is justified when it comes to the sale of meat or its deep processing. For personal consumption, competent poultry farmers raise broilers in an open way, like an ordinary chicken, with walking and grazing.