Content

During rainfall, a huge amount of water collects on rooftops and roads. It certainly needs to be taken into a ravine or drainage wells, which is what the storm sewer does. Many saw along the roads huge trays, covered with lattice on top. This is the drainage system, but not the whole. A complete stormwater drainage system involves the use of several elements that form the main units for collecting water.

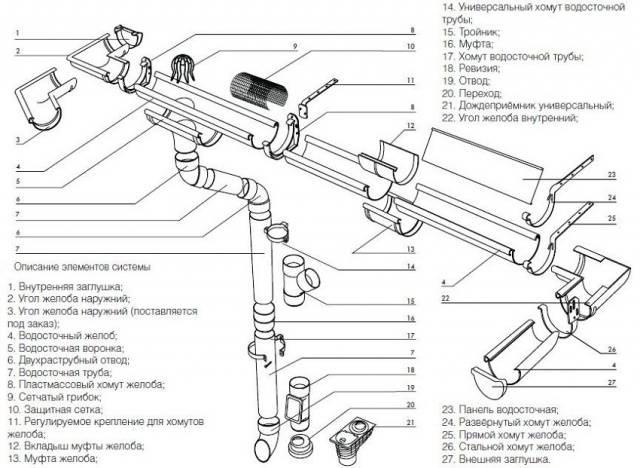

The device of the drainage system

The photo shows a diagram of a system that allows you to collect water from the roof of a building. This is only part of the drainage, because the drains then need to be put somewhere. The general scheme of storm sewer consists of the following units:

- storm water inlets;

- pipeline;

- drainage wells;

- filters.

Each node has a characteristic variety, and plays a role. Next, we'll take a look at each element individually. This will make it easier to understand the principle of the storm sewer system, as well as its structure.

In the video, the device of the drainage system:

Storm water inlets

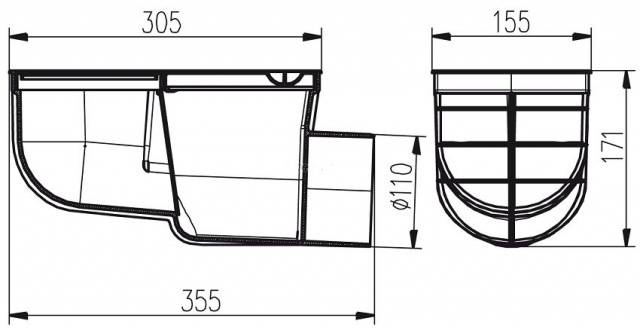

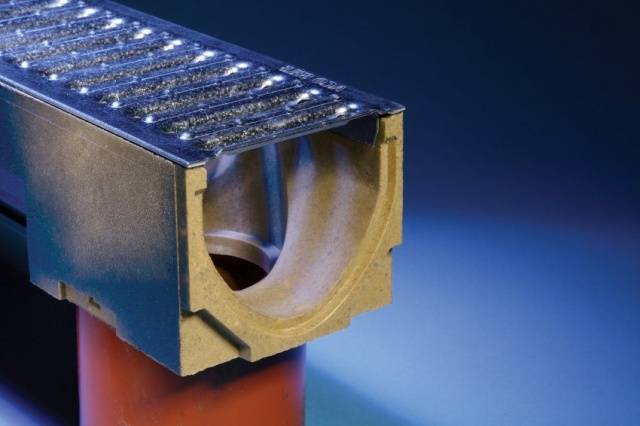

Often this element of the drainage system is called a water intake. The essence does not change from this. The design is designed to receive rain or melt water. This is where the name came from. Storm inlets of various sizes, shapes, depths, and also from different materials are produced. From above, the trays are covered with a strong grate.

W \ w trays

Concrete trays for storm sewers are used in road construction. Stormwater inlets are installed to collect wastewater in places where high pressure is applied to the structure. Depending on the grade of concrete used, there are three types of reinforced concrete trays:

- Lightweight storm drains are manufactured with a maximum wall thickness of 2 cm. The structures are cube-shaped. A light water intake is mounted under the descent of the downspout from the building, and a plastic outlet is used as a connecting element.

- A heavy concrete rainwater inlet is designed for a load of up to 3 tons. Such water inlets are installed along small roads, at sites where cars are expected to enter. The trays are made of fiber-reinforced concrete with a wall thickness of more than 2 cm. From above, the drainage structure is covered with a galvanized cast-iron grate.

- Trunk trays for storm sewers are distinguished by their collapsible design. The water inlet consists of several parts, which simplifies the process of its installation. Reinforced concrete is the material for the manufacture of trays. The minimum wall thickness is 5 cm. Cast iron grates are used to cover the trays. Reinforced concrete structures can withstand heavy loads, so their place of installation is on highways.

In private yards, when laying a drainage system, concrete storm water inlets are practically not used due to their large dimensions and weight, as well as the complexity of installation. And in road construction, reinforced concrete trays for storm sewers are gradually being replaced by more reliable cast-iron water intakes.

Cast iron trays

This type of storm water inlets is also used in road construction. The structures are made of cast iron grade SCH20, resistant to heavy loads, as well as to the effect of aggressive impurities in water.

Depending on the shape and permissible load, cast iron trays are produced in the following modifications:

- Small storm water inlets for storm sewers "DM" are produced in rectangular shape.One tray weighs at least 80 kg, and withstands a maximum load of up to 12.5 tons. Small water collectors are installed in the courtyard near apartment buildings or along a not busy highway.

- Large-sized rain hoppers "DB" are designed for a maximum load of 25 tons. The trays are rectangular and weigh at least 115 kg. The installation site is large highways, parking lots and other similar places with a large number of passing vehicles.

- Round-shaped storm water inlets "DK" are temporarily installed instead of rectangular trays when they are sent for repairs. The structure weighs approximately 100 kg, and is designed for a load of up to 15 tons.

From above, the trays are covered with cast iron grates. For reliability, they are fixed with bolts.

Plastic water intakes

In private construction, the most demanded are plastic storm water inlets. Their popularity is based on their light weight, ease of installation and long service life. Each type of plastic tray is designed for a certain load, which is indicated by the letter marking of the product:

- A - up to 1.5 tons. Storm inlets of this class are intended for installation on sidewalks and other areas where vehicles do not enter.

- B - up to 12.5 tons. The tray will withstand the load from a passenger car, therefore it is mounted in parking lots, near garages, etc.

- C - up to 25 tons. Water collectors can be installed at gas stations and on motorways.

- D - up to 40 tons. The grate of this storm water inlet will easily support the weight of the truck.

- E - up to 60 tons. Similar models of water intakes are installed on road sections and areas with heavy traffic loads.

- F - up to 90 tons. Storm water inlets are designed for specially equipped areas for heavy equipment.

All plastic storm water inlets are manufactured with a branch pipe downward or to the side for water drainage. The choice of model depends on the place of its installation in the drainage scheme. The top of the trays is covered with a plastic grill.

Composite headers

Two types of trays are produced:

- polymer concrete products are made of concrete with the addition of plastic;

- polymer sand trays are based on similar materials, but sand and additives are also used as additives.

According to their characteristics, composite water intakes have found their place between reinforced concrete and plastic trays. Unlike concrete storm water inlets, products made of composite materials are characterized by lighter weight, smooth surface, but withstand less load. If we compare trays with plastic counterparts, then composite products from them are heavier, but stronger. From above, storm water inlets are covered with cast iron or plastic gratings.

Metal water intakes

Metal water intake trays are not very popular due to the fact that the material quickly corrodes. To increase the service life of the storm water inlet, its walls must be made of thick steel or stainless steel. This option is not profitable in terms of cost and high weight. If it becomes necessary to install a metal water intake, then cast-iron models are preferred.

Drainage pipes

So, the collected water now needs to be taken to a sewer or drainage well. For this purpose, pipes are used in the storm sewer system. They are also made from different materials. Let's look at what kind of pipe is for a storm sewer, and in favor of which one to give preference to:

- Asbestos-cement pipes were used in the last century, and still have not lost their popularity. Such a pipeline is resistant to corrosion, rather strong, and has a low linear expansion. The disadvantage is the large weight of the pipe and its fragility, which requires careful transportation and laying.

- Metal pipes are the only way out if you need to lay storm sewers in an area with high mechanical stress. The disadvantages are the complexity of pipeline installation, high cost and metal instability to corrosion.

- Plastic pipes are available with a smooth wall or corrugated. The fact that the drain pipe is intended for outdoor installation indicates its orange color. Smooth-walled PVC pipes cannot be bent, therefore fitting of fittings is required when cornering. It is more convenient to use corrugated pipes for storm sewers because of their flexibility.

In private construction, preference is given to plastic pipes. They are lightweight, do not rot, are cheap and can be easily assembled by one person.

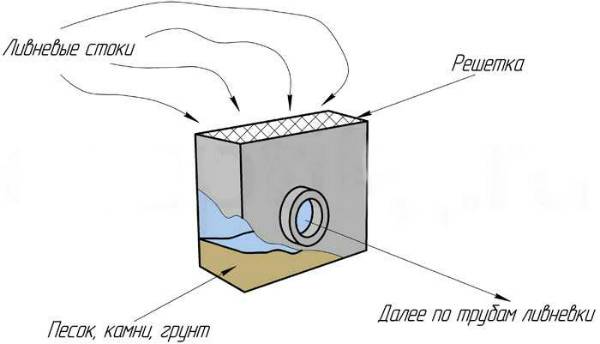

Trash box

There are different types of storm drain traps, but they all perform the same function and have a similar design. The filter housing forms a container. Above its bottom, there are passages for connection to the pipeline. The trash box has a filter grid that catches solid particles.

The principle of the filter is simple. The water moving through the pipes enters the sand trap. Solid impurities under the influence of gravity pass through the grate, settling at the bottom of the container. Already purified water comes out of the sand trap, and moves further through the pipes to the drainage well. The filter is periodically cleaned of sand, otherwise it will cease to cope with its duties.

Wells

The drainage of water from the storm sewer goes to a ravine, a drainage well or to a treatment plant. Drainage, intermediate and sewer wells have a simple design. In principle, this is a container of a certain size buried in the ground.

The complex device has a distribution well installed in the system to drain wastewater of different degrees of pollution. The design is a plastic container with one inlet and two outlets. The well is equipped with a neck, which can be covered with a cast-iron hatch on top. A ladder is fixed inside for the descent.

The flow is distributed according to the bypass principle. Dirty water enters the well through the inlet pipe. The outlet pipes are installed one above the other. Dirty liquid with heavy impurities is discharged through the lower outlet and directed to the treatment plant. Less contaminated water leaves through the upper outlet, and through a bypass channel - bypass is directed to a drainage well or other drainage point.

Let's summarize

These are all the main components of the storm sewer nodes. At first glance, the drainage system looks very simple, but it is not. Accurate calculations and correct installation are needed in order for the storm sewer to cope with the maximum volume of wastewater.

Stormwater is good. Last year I laid the plastic gutters myself. Now, after the rain, there are no puddles under the foundation. This problem is rarely paid attention to, but in vain. Then they complain that the house is cracked or the rooms are damp.