Content

There are many drawings and designs, how to make a snow blower do it yourself and this collection is constantly growing. This is due to the exclusive performance of the technique, since each craftsman makes his own adjustments. One rule remains unchanged for homemade products. Users recommend assembling a single-stage auger machine to residents of the middle lane. The two-stage screw rotor unit is more difficult to assemble, but it has a high performance. It is optimal to have such a snowblower for residents of snowy regions.

Features of the device of snow removal equipment

Any do-it-yourself snow blowers created may have slight differences in the design of the mechanisms that make the machines exclusive. But the craftsman assembles the main working units using an already developed scheme. To search for such a project, it is enough to dive into the Internet or contact a friend who has already made a snow blower for the house.

Let's start an overview of the snow blower device with the engine. It can be electric or gasoline powered. The machine with an electric motor is easier to manufacture, more economical to operate and requires little or no maintenance. A snow blower with a gasoline engine is much more powerful, it is not afraid of moisture, plus the car becomes mobile due to the lack of attachment to the outlet.

A feature of the device of snowplowing equipment is the presence of a rotor or auger. Combined models have both nodes. The rotor is an impeller with blades rotating on bearings inside a steel casing. It's easy to make. Harder for snow blowers to do screw... Here you need to develop drawings.

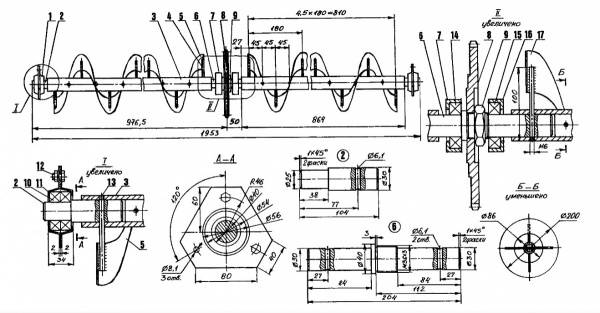

The sequence for assembling the auger is as follows:

- The shaft is made from a pipe, welded at the ends of the bearing trunnion, and two rectangular steel plates in the center. These will be the shoulder blades.

- Four discs with a diameter of 280 mm are cut from thick rubber or steel with a thickness of 2 mm.

- A hole is drilled in the center of each workpiece, equal to the thickness of the shaft, after which one side of the resulting ring is sawn.

- A spiral is bent from the cut disk and fixed to the shaft. On the left side, two discs are placed with directed turns towards the blades. Do the same on the right side of the shaft.

Bearings No. 203 or other suitable size are fitted on the trunnions. For fastening the auger under the bearings, hubs are made from pipe sections. The blanks are bolted to the side shelves of the snow receiver body.

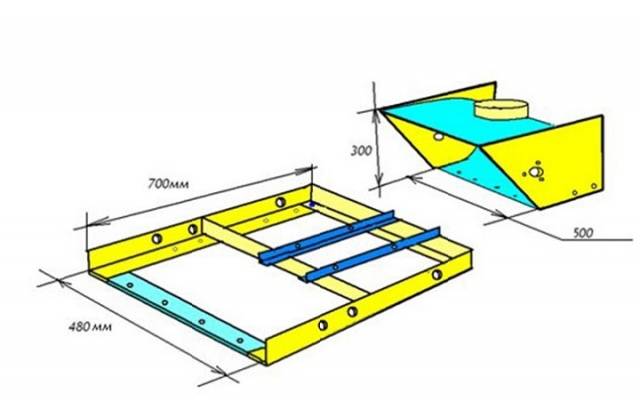

The snow bucket is made of sheet steel. To do this, take a strip with a width of 500 mm and bend it with an arc with a diameter of 300 mm. The sides can be sewn up with plywood or metal. A hole with a diameter of 160 mm is cut out in the center of the upper part of the snow receiver, to which a sleeve is attached to eject snow. The finished structure is installed on the frame. It is welded from metal corners.

Now it remains for the made snow blower to create a drive. That is, you need to make the auger rotate. There are several options for how to make the drive yourself:

- The rotary auger snow blower can be equipped with a gearbox. It is installed instead of the blades, and the screw shaft is made of two halves.

- Belt transmission is provided by two pulleys.One stands on the PTO of the motor, and the other is mounted on the auger shaft.

- The chain drive is arranged similarly to the belt drive, only sprockets from a moped or bicycle are used instead of pulleys.

- If a homemade snow blower assembled with your own hands as a nozzle for a walk-behind tractor, you can make a combined drive. In this case, the motor shaft is connected to the intermediate gear by a belt drive, and the torque from the gear shaft to the auger is transmitted by a chain drive. The principle of such a connection is shown in the photo.

Of all the options, the belt drive is considered the simplest, so it is most often installed by craftsmen on their snow blowers.

Examples of self-made snow blowers

Now we will look at how a do-it-yourself snowblower is assembled with an engine from various equipment, and also consider the option of a nozzle for a walk-behind tractor.

Electric snow blower

An electric model of a snow blower is more suitable for a summer cottage where you have to remove snow rarely and in small quantities. Usually, instead of a screw, such machines are equipped with one rotor operating on the principle of a fan. After the snow is captured by the guide vanes, the fan blades mix it with air and eject it under pressure through the outlet sleeve.

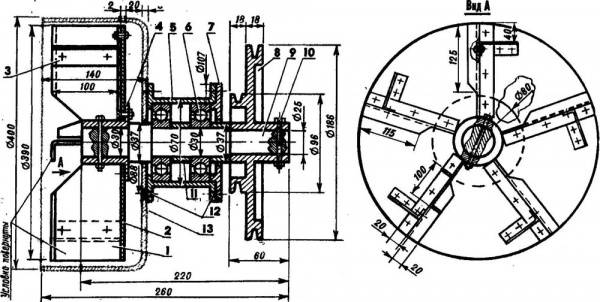

The rotor design is simple. It can be made according to the drawing.

For the impeller, a metal disk is taken and blades from a steel strip are welded onto it. There can be from 2 to 5 pieces. The shaft is turned on a lathe from a steel bar. Two bearings are mounted on it together with the hubs.

For the snail body, a part of the metal barrel is cut from the bottom side with a height of 150 mm. A hole is cut on the side, where a branch pipe is welded for fastening the sleeve. A hole is drilled in the center of the bottom, the rotor shaft is inserted so that it is inside the volute. An impeller is placed on it. The rotor bearing hubs are bolted to the bottom of the barrel from the outside of the volute. Two rectangular sheets are welded from the front of the case. The vanes will grip the snow and the fan will suck in, grind and throw it out.

The finished rotor mechanism is placed on the frame, connected by a belt drive with an electric motor, and wheels from a wheelbarrow are used as a running gear.

Snow blower with gasoline engine

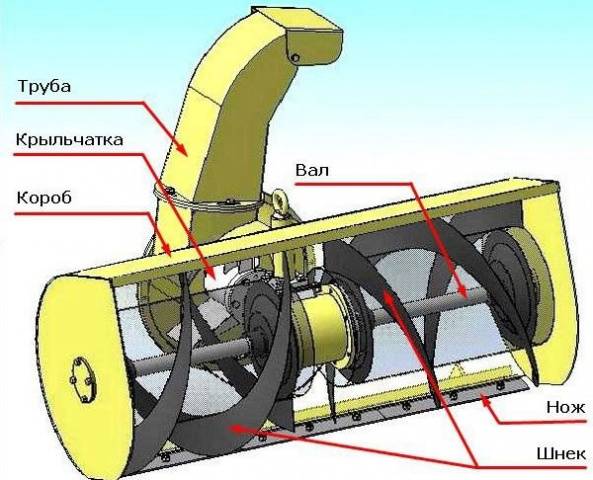

Gasoline-powered snowblowers are usually made with auger mechanism or combined. The first option is much simpler. We considered the manufacture of the screw above. For a combined snow blower, you need to additionally assemble the rotor as was done for the electric model. Only the guide vanes are not welded to the rotor housing. It is connected to the back of the auger snow collector.

The engine will fit any air cooled engine. It can be two-stroke or four-stroke. The frame of a non-self-propelled car is placed on the skis. It will be easier for the operator to push the snow thrower over thick cover. If the power of the motor allows you to make a self-propelled machine, then you will need to fix the wheels to the frame and connect them with a drive to the engine PTO.

Hitch on a walk-behind tractor

The simplest snow blower is a hitch on a walk-behind tractor. If there is a traction unit in the yard, then why create another machine with a stationary drive. As a hinge, it is necessary to make a screw mechanism with blades for ejecting snow. The body of the snow receiver is placed on the frame. The skis are attached from below. On the back of the frame, fasteners are welded, with the help of which the nozzle will be coupled to the walk-behind tractor.

The drive is carried out by a belt drive. The rotation speed of the auger can be adjusted by selecting pulleys of different diameters. If this cannot be done, then you can set between walk-behind tractor and auger intermediate reducer nozzle. It will reduce the rpm to the desired frequency.

The video shows the work of a homemade snow blower:

A home-made snow blower with its parameters practically does not differ from factory-made analogues, but it will cost the owner several times cheaper.