Content

A garden blower consists of a housing, inside which a fan rotates at high speeds. The impeller is powered by an electric or gasoline engine. A branch pipe is attached to the unit body - an air duct. Air comes out of it under high pressure or, conversely, is sucked in by the vacuum cleaner method. For what purposes the unit is intended, and how to make a blower with our own hands, we will now try to figure it out.

Difference of blowers by engine type

The main working element of the blower is the fan. To make it rotate, a motor is installed inside the unit housing.

Electric models

Blowers with an electric motor have a small power. They work almost silently, are characterized by light weight and small dimensions. The connection is carried out by carrying it to the outlet, but there are also rechargeable models. Electric blowers are designed for small areas.

Petrol models

Gasoline powered blowers are quite powerful. They often have a mulching function. Such units are characterized by high performance and are designed to handle large areas.

Models without engine

There are blowers without a motor. They are attachments to other equipment. Take a trimmer blower, for example. This nozzle consists of a housing with a fan inside. Connect it to the trimmer bar instead of the working head. Such a blower is intended for blowing off small debris from garden paths.

Working Modes

All blowers differ in technical characteristics, but they are capable of performing only three functions:

- Blowing air out of the nozzle. The mode is intended for blowing off debris, accelerating drying of a damp surface, fanning a fire and other similar work.

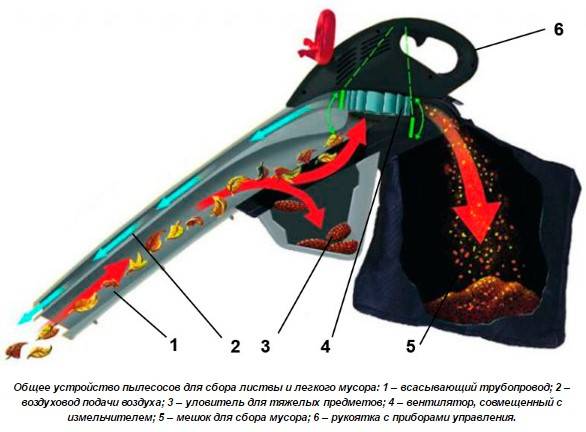

- Air suction through a nozzle. Basically, it's a vacuum cleaner. Leaves, grass and other light objects are drawn in through the nozzle, after which everything accumulates in the trash can.

- The mulching function works by drawing in air. Organic waste gets into the body, where it is ground into small particles. Further, the entire mass is used for composting.

The manufacturer offers the consumer models with one and several modes of operation.

Self-made blower

To quickly understand how to make a powerful blower with your own hands, just look at the old Soviet vacuum cleaner. It has two outputs: a suction nozzle and an exhaust. If you have such a unit, you do not have to do a garden vacuum cleaner with your own hands. He's already ready. Putting a hose on the exhaust gives you an air blower or garden sprayer. Here you can even save on a spray, as it is included in the kit in the form of a nozzle on a glass jar.

You need a vacuum cleaner function, just move the hose to the suction nozzle. Naturally, any attachment must be removed from it. The resulting garden vacuum cleaner will easily pick up small debris from the sidewalk. The operator only needs to frequently empty the bag of accumulations.

A small do-it-yourself electric blower will come out of a box for computer disks. The manufacturing procedure is as follows:

- The transparent cover is removed from the round box. A protrusion is cut from the second black half with a knife, onto which the disks are strung.An electric motor shaft from a children's toy is inserted into the resulting hole, and its body itself is glued with a hot gun to the wall of the box.

- The bottom is cut off from a plastic liter bottle. A hole is cut on the side for the power wires of the electric motor. The made glass is glued with a hot gun to the black half of the box. This will be the protective housing for the motor.

- Now you need to make the fan itself. First, they take a wide cork from a plastic bottle, mark the threaded rim into eight identical segments and make cuts along the markings. The impeller blades for the fan are cut out of thin sheet metal. You can dissolve an empty deodorant can. Eight rectangles are cut out of the workpiece, inserted into the slots on the cork and glued with a hot gun.

- The fan impeller is almost complete. It remains to drill a hole in the center of the plug and push it onto the motor shaft. The blades need to be bent a little in the direction of rotation. This will increase the pressure of the blown air. To speed up the process, instead of a homemade fan, a computer cooler can be installed in the box.

- Now you need to make the snail itself. A hole is cut in the side of the transparent half of the box. A piece of plastic water pipe is leaned against it, after which the joint is carefully pasted over with a hot gun. The result is a blower nozzle.

Now it remains to connect the two halves of the box and apply voltage to the motor. As soon as the fan starts to rotate, air will flow from the nozzle.

A master class on making a blower from a disc box can be watched in the video:

A blower is a unit for a specific purpose and is not a basic necessity, but sometimes its presence can help out in a difficult situation.