Content

A lot of modern technology has been invented for snow removal, but shovel and remained an irreplaceable assistant in this matter. The simplest tool is in demand for cleaning sidewalks by owners of private yards and city janitors. If desired snow shovel do it yourself can be made from any lightweight but durable sheet material. Let's look at several options for making a snow plow.

Plastic shovel

The most comfortable for cleaning and throwing snow is considered a plastic shovel. The scoop is easier to buy at the store. At home, all that remains is to plant it on the handle and fix it with a self-tapping screw. The lightweight shovel is very handy. The strength of the scoop is ensured by the ribs cast from plastic, and the edge of the blade is protected from abrasion by a steel strip.

You can make a shovel for snow from PVC sheet with your own hands using the following method:

- For the scoop, you need to find a piece of plastic. The sheet must be durable and flexible at the same time. It can be tested by flexion, of course, within the limits of the mind. If the plastic has not burst, then the scoop will turn out to be excellent.

- A scoop shape is drawn on a plastic sheet. The most convenient size is 50x50 cm. Cut out the workpiece with a jigsaw. Burrs on the plastic do not need to be cleaned. They will wear off when cleaning the snow.

- The most difficult job is to attach the handle. It is fixed in the center of the scoop with sheet steel overlays.

To make the canvas resistant to abrasion, the working edge of the scoop is bent around with galvanized sheet steel and fixed with rivets.

Aluminum snow shovel

Metal shovels are superior in strength, but they are heavy for clearing snow. The only exception is lightweight aluminum. The soft metal is great for the scoop. Let's take a look at how to make a sheet aluminum snow shovel:

- An aluminum scoop is best made with bumpers. When marking a sheet, the shelves should be marked on three sides of the workpiece. A stalk will pass through the tailgate, so its height should be 1–2 cm greater than the thickness of the wooden element.

- Aluminum is easy to cut. For cutting, metal scissors, an electric jigsaw, or in extreme cases, you can use a grinder, are suitable. On the cut out fragment, the sides are folded on three sides. In the rear shelf, a hole is pre-drilled with a diameter equal to the thickness of the handle.

- In the center of the scoop, a nest for the handle is attached with rivets. It is made from a piece of sheet aluminum. The workpiece is placed on the edge of the cutting and trying to press down its edges. Next, the aluminum plate is tapped with a hammer until a semicircle is squeezed out. The end result is a scoop, as shown in the photo.

Now it remains to take the handle, pass it through the hole in the back side of the scoop and insert it into the nest. So that the shovel made does not fly off while throwing snow, the end of the handle is fixed with a self-tapping screw to the nest.

Step-by-step instructions for making a wooden shovel

To make a shovel for snow removal with your own hands, prepare: plywood, a wide pine board, a bar for a handle, galvanized sheet steel and woodworking tools. If all this is available, then boldly go ahead:

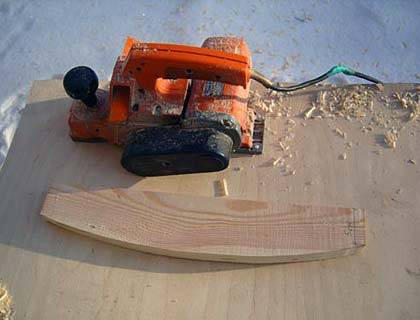

- First, from a pine board 50 cm long, you need to make a base for fixing the handle and plywood. That is, the tailgate of the scoop. The board is taken with a minimum width of 8 cm.From both its ends along the end sides, segments of 5 cm are marked. Further, from the center of the side of the board, they begin to cut the corners with a plane to the marks. In the final, a blank should be obtained, with a flat and semicircular side.

- The finished part is processed with a plane. Can be additionally sanded with sandpaper.

- The handle is made of a bar with a section of 40x40 mm. First, give the workpiece a rounded shape with a plane, and then carefully grind the handle with fine-grained emery paper.

- The next step on the basis is to make a seat for the handle. The recess is selected with a chisel in the center of the board. Do this on a flat side. The width of the recess is equal to the thickness of the handle, and in depth add 5 mm to the bevel of the handle. To excavate, first make 2 cuts with a hacksaw, and then remove the piece of wood with a chisel.

- When all the details are ready, they make a control fitting. Plywood is bent around in a semicircle of the base and the places of the cut are marked. The end of the handle is cut obliquely. The cut should fit snugly against the plywood, and the handle itself should lie inside the notch.

- The identified shortcomings during fitting are corrected. A sheet for a scoop is cut out of plywood according to the marking, after which all the blanks are once again sanded at the cuts.

- It's time to connect all the blanks. First, the edge of the plywood is applied to the semicircular side of the base. The first nail is driven in the center. Further, the plywood is pressed against the base, giving the scoop a semicircular shape and, as it bends, continues to nail the canvas. Instead of nails, you can screw in self-tapping screws.

- The finished scoop is turned over with the base up and the handle is applied. An oblique cut of the cutting is placed in the center of the working blade, while it is inserted into the groove on the base. If everything fits perfectly, the handle is nailed down.

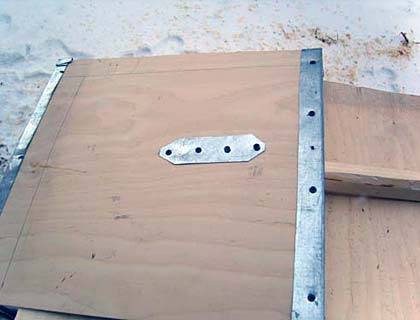

- Now it remains to sheathe the working edges of the scoop with zinc. For this, 2 strips 5 cm wide are cut from the sheet. One of them must be bent in half in length. The resulting U-shaped blank is put on plywood, where the scoop will be working edge. The steel strip is compacted by tapping with a hammer, and then fixed with rivets.

- The other abraded part of the scoop is closed with the second strip - the plywood joint with the semicircular side of the base. The galvanized steel is screwed on with self-tapping screws. The edges of the strip can be folded over the sides of the scoop base. To prevent the handle from breaking out of the groove, it is also reinforced with a piece of steel strip.

- The shovel is ready, but it's not the end yet. Turn the scoop over. Where the handle is nailed to the plywood, a piece of steel strip is applied and 3-4 self-tapping screws are screwed in. Such reinforcement will not allow the working blade to come off the handle under the weight of the snow.

Now we can say that the do-it-yourself snow shovel is completely ready.

The video provides instructions for making a shovel:

Auger snow shovel

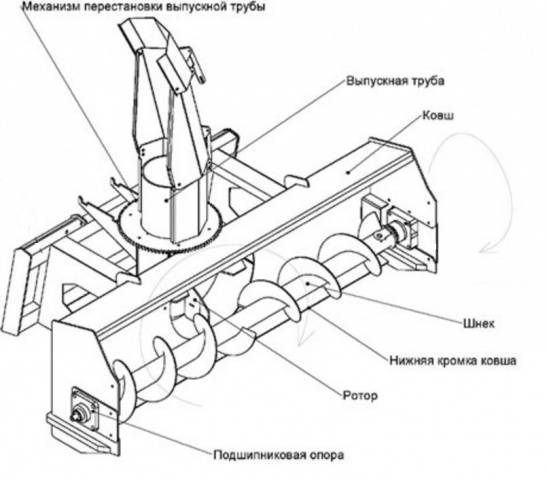

The auger shovel is characterized by high performance, but it is not easy to assemble it. First, you need to draw the correct drawings. Secondly, you need to understand how the auger works. A diagram of the factory mechanism can be seen in the photo. We will now deal with the operation of auger snow removal equipment.

So, let's start with the fact that the working mechanisms themselves - the augers are installed in the inside of the steel snow collection chamber. Its lower edge moves along the hard surface of the road just like a bulldozer knife does. At this time, the layers of snow are captured. Rotating augers guide it to the top of the chamber, where the outlet is located. It can be centered or offset to the side, depending on the size of the shovel. Typically, the central location of the outlet is observed for auger shovels with a width of 1 m or more.

The rotation of the augers directs the snow to the outlet, but they are not able to push it out of the snow collection chamber. The throwing blades are responsible for this work. They revolve together with augerpushing the supplied snow into the opening of the nozzle.

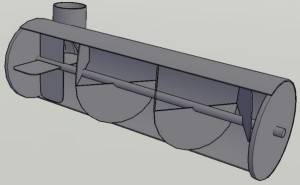

According to the principle of a factory analogue, you can make a homemade auger snow blower. The semicircular body of the snow receiver can be bent from galvanized steel. A hole is cut in the center or from the side and an outlet pipe is installed. The sidewalls need strong, because the bearings of the rotor mechanism will be fixed on them. For their manufacture, textolite or moisture-resistant plywood is suitable.

For the manufacture of the auger, a steel rod or pipe with a diameter of 20 mm is taken. This will be the shaft. The blades can be welded from sheet steel or made from dense rubber. In the second version, steel strips need to be welded onto the shaft. The rubber blades will then be bolted to them.

When making a screw, it is important to maintain the same pitch of the spiral of the blades and choose the correct direction of rotation. If the outlet is installed in the center of the chamber, then a rectangular throw-up blade made of metal with a minimum thickness of 5 mm is welded in the middle of the shaft.

Now it remains to fix the hubs to the side walls of the chamber, put the bearings on the shaft and insert the auger into place.

The tool will work by hand, like a shovel. To do this, wheels are attached to the side of the body, and a handle is fixed at the back of the camera. With large dimensions, the auger shovel is attached to the front of the walk-behind tractor.

Any snow removal tool is needed only in winter. The rest of the time it is stored in a dry place, preferably away from heating devices.