Content

Raising chickens is not very cheap for a poultry farmer. Most of the costs are associated with the purchase of feed. To reduce its loss, you need to choose the right feeders. It depends on their design how much the chicken will transfer grains. The best option is considered chicken feeder factory-made, but with knowledge of the matter, you can assemble it yourself.

Varieties of chicken feeders

Before making do-it-yourself chicken feeders, you need to deal with their varieties. This will help you decide which design you need.

Difference in materials

Feeders for chickens are made of wood, metal or plastic. The choice of material depends on what kind of feed the structure is designed for. So, the material difference is:

- The most common are wooden structures. They are intended for feeding chickens with dry feed. Wood is a natural material and is best suited for grains, dry compound feed, and various mineral additives.Advice! It is undesirable to use wooden feeders for raw food. Food debris will stick in hard-to-reach areas of the structure. Over time, they will start to rot, contaminating fresh feed with pathogenic bacteria.

- Chickens must include mash in their diet. Plastic containers are ideal for wet food as they are easier to clean to remove food debris. Steel containers are also suitable for these purposes, but ferrous metal tends to rust from exposure to moisture, and stainless steel is very expensive.

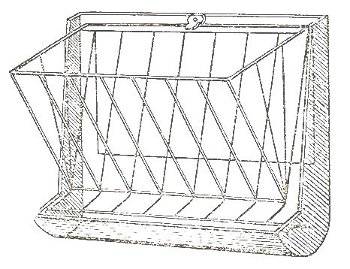

- Metal is appropriate to use in the manufacture of grass bins. Usually a V-shaped structure is made with a blank back wall made of sheet metal. The front side is closed with rods or mesh.

Correctly selected material for the feeder contributes to the safety of food, and, therefore, its economy.

Difference in feeding method

The convenience of feeding the bird depends on how the food will be fed into the feeder. After all, it is much more convenient to feed the chickens once a day than to run into the barn at short intervals.

According to the method of feeding, the feeders are divided into the following types:

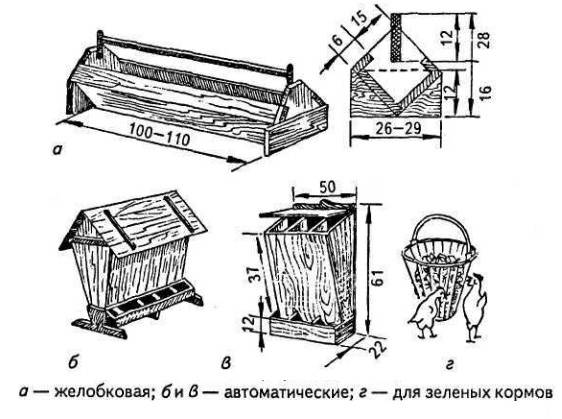

- The simplest tray model is more suitable for feeding young animals. The design is a conventional container with sides that prevent food from spilling out. Most often, such feeders are given an elongated shape.

- Grooved models are equipped with a pinwheel or demountable mesh. The interior of the structure can have dividing walls that form separate compartments for different feed. These feeders are usually placed outside cages for adult chickensso that they only reach for food with their head.

- Very good service bunker models. They are intended for filling dry feed and grain. Typically, the size of the hopper is based on the daily supply of feed. From below, the structure is equipped with a tray into which food is poured out of the bunker as the chickens eat it.

The photo shows an illustrative example of several types of chicken feeders. Automatic models are the same hopper feeders. They are simply called that because of the way the feed is fed.

Difference by location in the house

And the last thing that can differ chicken feeders is in their location. In a chicken coop or cage, two types of structures are used:

- The outdoor type is convenient due to its mobility. The capacity can be rearranged, if necessary, to any place in the chicken coop.

- The hinged type is fixed to the wall of the poultry house or cage. These feeders are convenient in terms of stability. In any case, the chicken will not be able to overturn the food container.

Sometimes poultry farmers practice using both types of feeders at the same time. The convenience of feeding chickens is determined empirically, which depends on the breed of the bird, age, as well as the characteristics of the room for keeping them.

What are the requirements for chicken feeders

There are few requirements for chicken feeders, and all of them are aimed at economical use of feed, and ease of maintenance. Let's take a look at three important points:

- The container for feeding chickens must have a protective device that allows rational use of feed. If the chicken has free access to food, it quickly rakes it up, throws it out of the container, plus droppings get into the feed. All kinds of turntables, nets, sides, lintels and other devices prevent the bird from carelessly handling the grain.

- A good feeder is one that is easy to maintain. The container needs to be filled with food daily, as it gets dirty, it is cleaned and even washed. Feeder material and design should facilitate maintenance. It is good if the container is collapsible, easy to clean and lightweight.

- The volume of the container should be sufficient for at least one-time feeding of the livestock, and the dimensions are selected so that all chickens have free access to food. To calculate the length of the tray, a minimum of 10 cm is allotted for each adult chicken. The chicks will have 5 cm of space in the feeder. In circular trays, each chicken is allocated 2.5 cm of free space.

With any device, there should be enough feeders to feed all chickens at the same time. If these conditions are not met, a strong bird will repel weak individuals from food.

Homemade chicken feeder options

Now we will look at several common options for making a chicken feeder from materials that are lying around in almost every yard.

Vertical bin made of PET bottles

The simplest version of a bunker made of plastic bottles is shown in the photo. For one design, you will need one container with a volume of 1.5, 2 and 5 liters. The manufacturing procedure is as follows:

- A feed hopper is made from a 1.5 liter bottle. For this, the bottom is cut off, and holes with a diameter of about 20 mm are drilled in a circle near the neck.

- The bottom is cut off from a two-liter bottle, leaving a side about 10 cm on it. This will be the bunker lid.

- From a 5 liter bottle, the bottom is also cut off, leaving a side about 15 cm high on it. We got a container where the feed from the bunker will pour out. Now a hole is drilled in the center of the cut bottom, the diameter of which is equal to the size of the threaded neck of a 1.5 liter bottle. The exact same hole needs to be made in a piece of plywood. It is needed for the stability of the feeder.

- Now all the parts are connected together. The bottom of a 5 liter container is placed on the neck of a 1.5 liter bottle, then a piece of plywood, and all this is pulled together with a cork. The feeder is ready.

We turn the structure over so that the cork of the 1.5 liter bottle is at the bottom. So, we have a vertical bunker. Pour the grains inside, and cover the reconciliation with a lid from the bottom of a 2 liter bottle. Through the holes near the neck, the food is poured into a container made from the bottom of a 5 liter bottle.

Two versions of the trough from a 5 liter bottle

A simple version of homemade chicken feeders is shown in the photo from a 5 liter bottle. Near the bottom, cut holes of arbitrary diameter with a knife in a circle so that the food spills out. Place the bottle in any larger bowl. Spacers are placed using copper wire, piercing the side walls of the bottle and bowl. Food is poured into the bottle through the neck using a watering can.It is poured into the bowl through the holes made.

In the second version of the design, the bowl can be omitted. The holes are cut 15 cm above the bottom of the bottle. The window is made in such a size that the chicken's head fits in there. The feed is poured through the mouth as in the previous design.

Bunker feeder for chickens

To make bunker feeder for chickens do it yourself plywood or sheet steel. First, design drawings are made. On a sheet of the selected material, draw the front wall of the bunker measuring 40x50 cm, and the back wall measuring 40x40 cm.In addition, draw two identical conical parts from which the side walls will be made. For the lid, draw a rectangle larger than the top of the bin.

All parts are cut with a jigsaw. The plywood bin is connected with hardware and rails. Steel fragments are welded by gas or electric welding. A gap is left at the bottom of the hopper for spilling feed. In the same part, an oblong tray is attached. For the convenience of filling the feed, the lid is hinged.

In the video, the bunker model of the feeder:

Auto Feeder PVC Pipe

Excellent do-it-yourself feeders for chickens are obtained from PVC pipes used for the construction of sewers. The photo shows the horizontal and vertical versions. In the first case, knees are put on both ends of a pipe with a diameter of 100–150 mm. Food will be poured here. In the side wall of the pipe, oblong windows are cut out through which the chickens will peck food. The structure is fixed horizontally to the wall with clamps.

For a vertical PVC feeder, pipes make a riser for filling grain. A tee and two knees are put on from below. This design is designed for two chickens. For one individual, instead of a tee, a knee can be immediately put on the pipe. In this case, you will have to collect a whole battery of such feeders by the number of heads.

In the video, a feeder and drinker for chickens:

Grass hopper

For the manufacture of such a bunker, you will need a welding machine and rods 6–8 mm thick. The photo shows an example of a grass feeder. For its manufacture, a V-shaped hopper is welded from rods. In the shed, it is simply attached to the wall or first fixed on plywood or sheet of tin, and then cling to a permanent place. A tray can be made under the hopper to prevent small grass from spilling onto the floor.

Conclusion

All self-made feeders are easy to use, as the feed is fed into them automatically. Grain can be poured in the morning, going to work, and a new portion can be added in the evening.