Content

- 1 Important characteristics of penoplex hives

- 2 Benefits of PPS hives

- 3 Disadvantages of Styrofoam Hives

- 4 How does the material affect the quality of honey

- 5 How to make a beehive from PPP with your own hands

- 6 Features of keeping bees in polystyrene foam hives

- 7 Conclusion

- 8 Reviews of beekeepers about styrofoam hives

Styrofoam hives have not yet received mass recognition by domestic beekeepers, but they are already found in private apiaries. Compared to wood, polystyrene is much lighter, is not afraid of dampness, and has less thermal conductivity. However, PPP is fragile, and its chemical origin is not always welcomed by beekeepers.

Important characteristics of penoplex hives

In beekeeping, styrofoam hives are not common. The material is used more in construction for thermal insulation. The new type of houses is being tested by private beekeepers. It should be noted right away that expanded polystyrene and polystyrene are externally similar materials, but differ in characteristics and method of production. Foam is the least suitable for making beehives due to its lower density, susceptibility to crumbling into small balls. Penoplex is a representative of expanded polystyrene.

If we consider these materials in general, then the hives from them turn out to be warm. In winter, the houses do not need to be covered, and in summer, the foam walls protect the bees from the heat. In addition, PPS has high sound insulating properties. Silence is always maintained inside the penoplex hive, the bees are constantly calm.

A big plus is the resistance of polystyrene, PPS and foam to moisture. Hives are able to stay in the rain for a long time. Compared to wood, the material is resistant to swelling, decay, deformation. PPP does not absorb moisture. After the rain, the hive remains light and can be easily moved to another location.

Factory-made PPS hives are easy to use. First, they are lightweight. Serving a foam hive is within the power of one person. Secondly, the parts of the collapsible design are interchangeable. If one element is broken, it is replaced, rather than buying a new hive.

Benefits of PPS hives

Positive traits reflect the feedback from professional beekeepers about Styrofoam hives. Ukrainian beekeeper Nakhaev N.N. found many advantages in using PPS hives in the spring. From personal observations, the beekeeper concluded that bees develop better in a penoplex house than inside a wooden structure. Polyfoam has poor thermal conductivity. It is easier for bees to maintain an optimal microclimate for brood development.

When the inside of the hive is warm, the bees spend less energy. Accordingly, feed consumption is reduced. In the hives of the PPS, productivity increases. The apiary brings in more income.

An important advantage is the convenience of transporting hives. Polyfoam, expanded polystyrene and polystyrene foam are very lightweight materials. It is easy to carry the hives, go to the countryside to increase the bribe.

Disadvantages of Styrofoam Hives

Penoplex hives have a number of disadvantages. They are connected not with the technology of keeping bees, but with the maintenance of the house. PPP and polystyrene are fragile. Careless disassembly of the housing leads to breakage of the connecting folds.The process of cleaning propolis becomes difficult. It will not work to scrape it off with a chisel. Propolis will peel off along with grains of foam or PPP.

A blowtorch cannot be used to disinfect the hive. Styrofoam and expanded polystyrene quickly ignite. You will need to additionally buy special disinfectants. The solution is used harmless to bees, polystyrene, polystyrene foam and PPS.

The light weight of the foam creates not only advantages when transporting the hives, but also brings many inconveniences. The houses have to be pulled together with soft straps, otherwise the wind will scatter the bodies. At the apiary, the covers of the hives of the PPS must be pressed with stones or bricks. Without fixation, they will be blown away by the wind.

How does the material affect the quality of honey

The first to appear were Polish and Finnish beehives made of expanded polystyrene, and later domestic manufacturers began to use penoplex for the manufacture of houses. Beekeepers were wary of the novelty. After all, styrene tends to accumulate in the body of bees and their waste products. However, scientifically, the harmfulness of PPS hives has not been confirmed. If there are accumulations of styrene, then they are in a scanty safe amount.

At the production site, penoplex, polystyrene foam, polystyrene foam are tested for toxicity by the SES services. In European countries, the material is allowed for the production of houses. Experts have proven that expanded polystyrene does not impair the quality of honey.

How to make a beehive from PPP with your own hands

To assemble a homemade polystyrene beehive, you will need to choose the right material. It is optimal to stay on slabs 50 mm thick. It is important to pay attention to the density of the foam or foam. The higher the indicator, the stronger the material, the higher the sound insulation, the lower the thermal conductivity. When choosing plates, it is better to give preference to penoplex or expanded polystyrene. They can be recognized by their porous structure, reminiscent of a foam rubber sponge. Polyfoam consists of small balls that crumble from abrasion by hand.

When assembling beehives from expanded polystyrene with your own hands, drawings are definitely needed. PPS plates are expensive. Drawings will help to optimally calculate the required number of sheets of expanded polystyrene, economically cut fragments.

Drawings of polystyrene beehives

The easiest option is to make a 6-frame PPP hive using foam sheets. Experienced beekeepers often use expanded polystyrene for assembly cores and Dadanov. If you wish, you can make a sunbed. A multi-body hive with 10 frames measuring 450x375 mm is considered widespread.

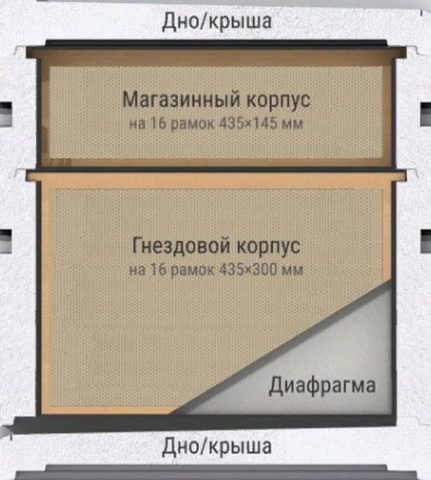

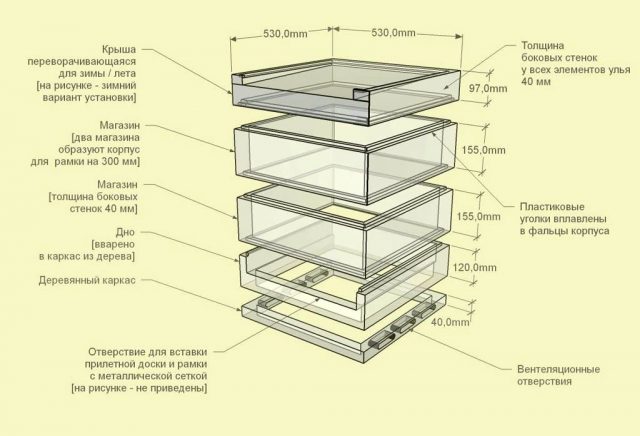

For professionals, do-it-yourself penoplex beehive drawings for 16 frames measuring 435x300 mm are more suitable. The house has a nest compartment (690x540x320 mm), a half-frame store (690x540x165 mm). The lid and bottom of the PPS hive have dimensions of 690x540x80 mm. Aperture size 450x325x25 mm. The modular house "Dobrynya +", produced by a domestic manufacturer, has similar parameters.

Preparation of tools and materials

First, materials are bought for making a hive. You will need PPP plates. The standard size of the foam sheet is 1.2x0.6 m. To fasten the elements, use glue, liquid nails, self-tapping screws up to 70 mm long. So that the inner folds under the frames do not break off, they are reinforced with metal corners. To draw the drawing and carry the fragments to the penoplex, you will need a Whatman paper.

Of the tools you will need:

- ruler 100 cm long;

- marker;

- sharp stationery knife;

- fine-grained sandpaper.

Additionally, a fine mesh steel mesh is required to cover the ventilation openings.

Build process

Home-made house PPP is assembled in the following sequence:

- a diagram is drawn on a Whatman paper, fragments are cut out, transferred to a sheet of penoplex;

- the expanded polystyrene plate is cut with a knife according to the applied markings;

- the cut out parts are sanded with sandpaper;

- elements of the front and rear walls of the house are equipped with folds for laying frames;

- the cut parts are glued together, the joints are reinforced with self-tapping screws with a pitch of 120 mm;

- from the outside of the hive in the penoplex, recesses are cut out for the handles.

The assembled house is tightened with straps until the glue hardens completely. The remaining slots are filled with polyurethane foam.

The final stage of work

After 1-3 days, the glue should completely harden. The hive is freed from the straps. The ventilation holes are covered with a steel mesh. Internal folds under the frames are pasted over with a metal corner. Outside, the PPS hive is painted with water-based facade paint.

Features of keeping bees in polystyrene foam hives

Hives made of polystyrene and polystyrene foam are not brought into the winter house, otherwise the insects will steam up. Houses hibernate on the street. The hives are pressed against each other with their sides for optimal heat retention. In spring, the increased activity of bees will come earlier than in wooden houses. Early brood will appear. During this time, it is important to open the ventilation holes to remove moisture. In summer, it is optimal to replace the bottom made of expanded polystyrene with a mesh.

If there are wooden beehives in the apiary, then it is better to plant strong families there. Weakened layers are left in foam or foam houses. For the winter, the nests are not insulated. Outside, the hives are constantly supported with colored emulsion with a color scheme, otherwise the PPS will begin to disappear under the sun.

Conclusion

Styrofoam hives are the best solution for keeping weakened families. In winter, an optimal microclimate is maintained inside the house, insects spend less energy, and consume food sparingly.